It is our training, process, and technology that sets a new standard for quality in valve repair. We identify and solve issues before failure through our comprehensive MOV Diagnostics and Preventive Maintenance Program.

Equipped with an experienced team of experts and the latest technology, we achieve the following for you:

Equipped with the latest in diagnostic and repair technology and a reliable team of experts, we can identify core issues and solve them faster than ever before.

Our team gives quick solutions for the following common maintenance problems:

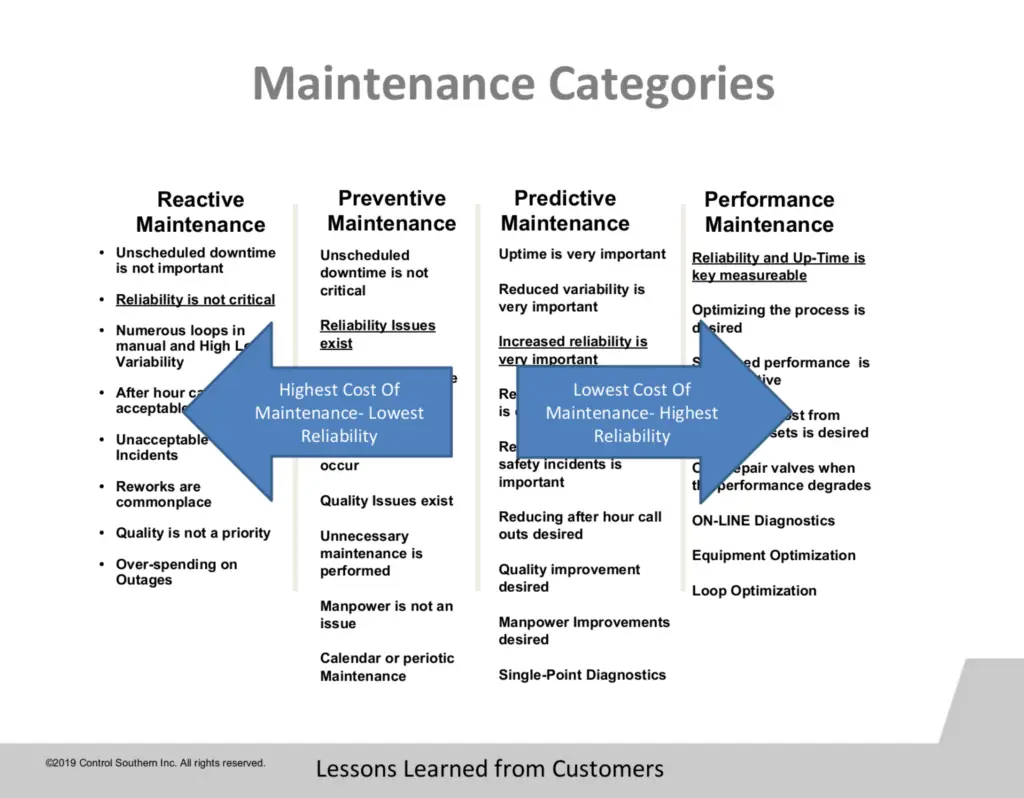

Wherever you are on the performance maintenance journey, we provide the support you need through our NYNE Sure Service Program.

It’s a Reliability Centered Maintenance Program that continually progresses you towards performance maintenance with the following:

We use instrumentation, digital tools, and an experienced team to measure and monitor valve condition. Our team mitigates and prevents failures through plotting and trending mechanical wear, instrument degradation and electric degradation which assists our customer with data driven decisions that impact plant availability and run time.

We repair all types of actuators with expertise in Limitorque, Rotork Bettis, EIM, Rexa, Auma, Biffi, and all other brands of electric actuators.