Our in-house valve training has been certifying many in the industry for decades; our safety training and process ensures full compliance with OSHA; quality standards are set to manufacturer specifications; and our diagnostic and repair equipment have the capabilities to identify issues more quickly and repair to a much higher standard.

Safety Relief Valve Repair & New Assemblies

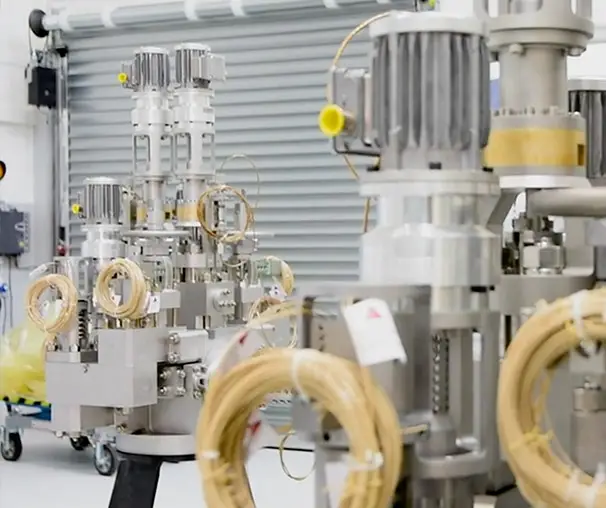

Isolation Valve Repair

Pneumatic & Electric Actuator Repair